Description

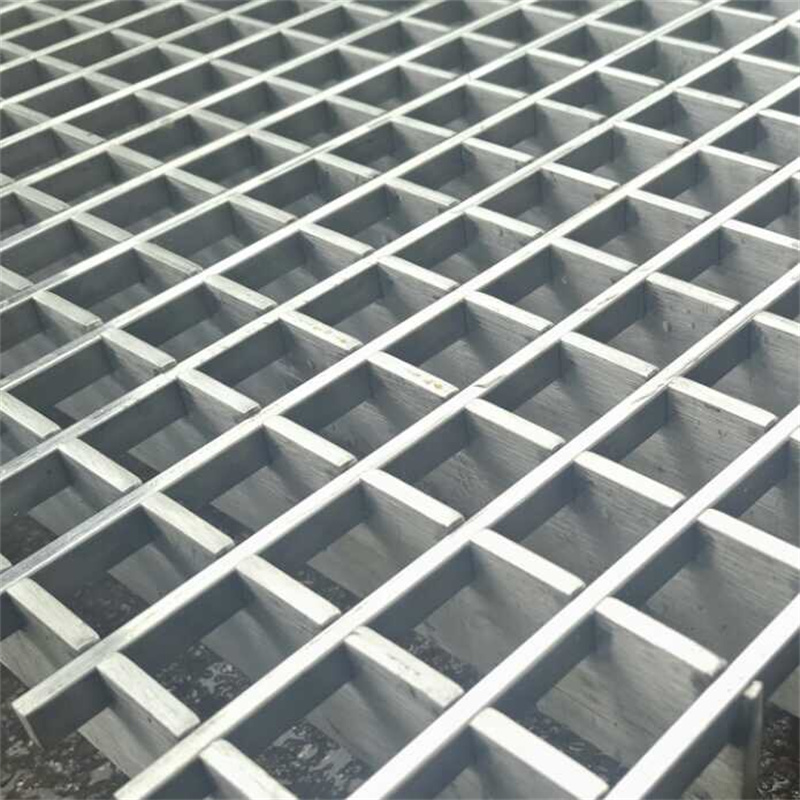

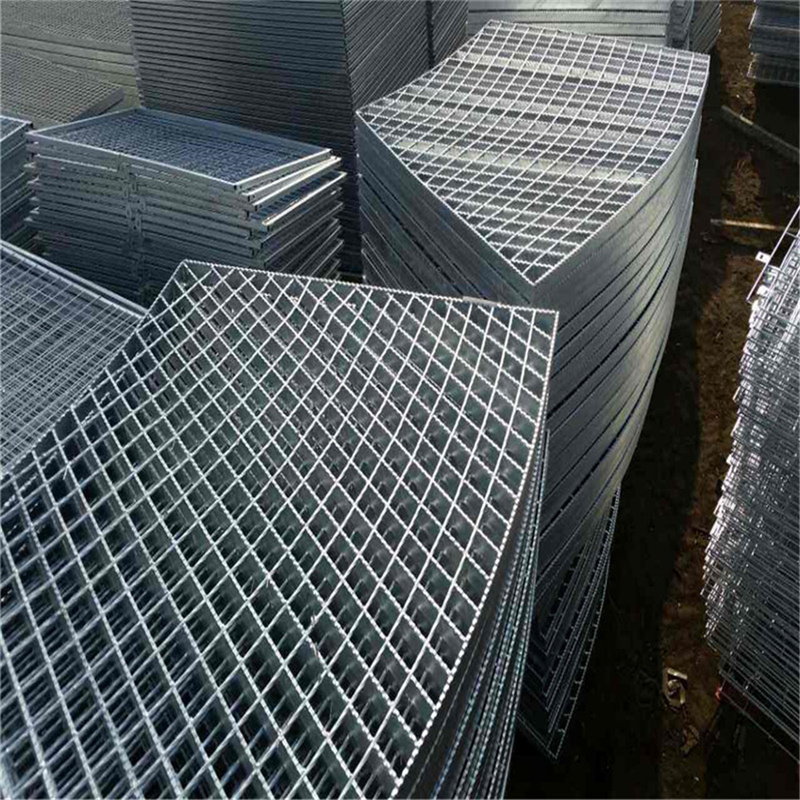

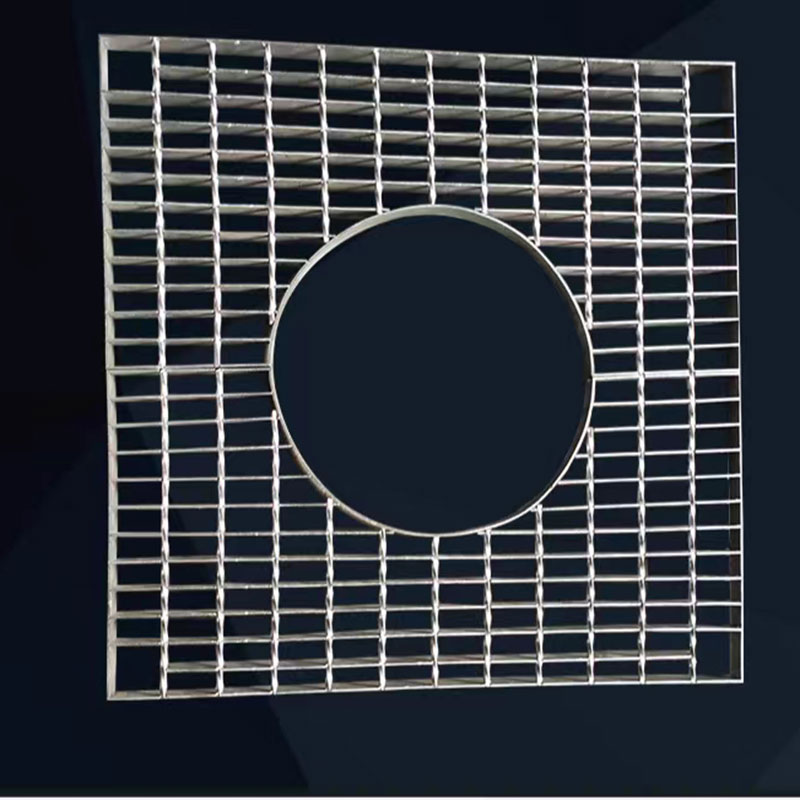

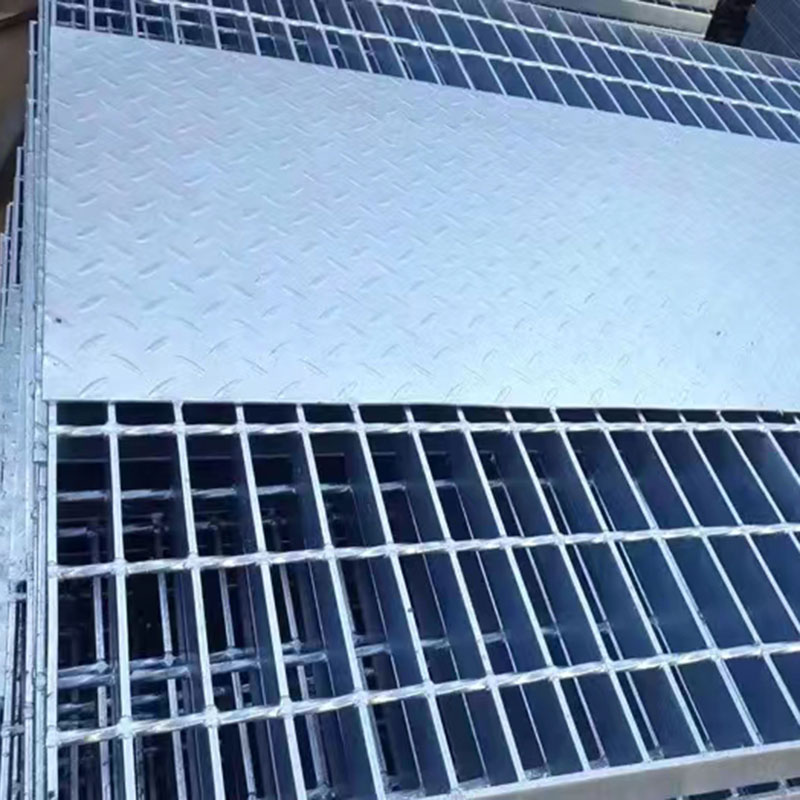

Press-locked steel grating also can be called pressure locked grating, it is made of low carbon steel or stainless steel. With the performance of high bearing capacity, non-slip, anti-corrosion and easy to install and remove, pressure locked grating is widely used for ceilings, platforms, floors, fence and all kinds of cover in the factories, civil and commercial buildings. Two press-locked steel grating with different mesh sizes which people often use: 33 mm × 33 mm, 33 mm × 11 mm. Introduction to steel grating: Off inserted steel grating is a kind of carrying capacity of large steel plate products, it consists of a certain size of Q235 low carbon steel flat by the slot (hole), plug, welding, finishing processes such as manufacturing and become a kind of steel plate products, also can choose stainless steel, brass plate, aluminum plate for the material, this product can be widely used in the ditch cover plate, stair step plate, pool cover plate. The specification of the steel grating Bearing flat steel spacing: 30 40 60 (mm) horizontal bar flat steel spacing: 30 40 60 (mm) flat steel width: 20-60 (mm) flat steel thickness: 3mm 4mm 5mm various specifications can be customized according to customer needsThe characteristics and application of steel grating: Our company produces the PLUG grid plate solder joint firm, the hole distance is even, the net surface is flat, the design is beautiful, practical, not only make supplies, but also works of art, over the years has developed hundreds of varieties, export products favored by customers. It is widely used in civil and commercial buildings, theaters, subway, city rail and other municipal engineering fields, which can be used for suspended ceiling, indoor and outdoor decoration, platform walkway, ventilation window (well), advertising plaque, various cover plates, etc.Introduction to the inserted steel grating The inserted steel plate, also known as the inserted steel plate, is made of a certain size of ordinary low-carbon flat steel, stainless steel, brass plate, aluminum plate through the process of slotting (hole), inserting, welding, finishing and so on. Product solder joint firm, uniform hole distance, beautiful design, convenient and practical. The inserted steel lattice plate has the characteristics of high strength, corrosion prevention and maintenance free of ordinary steel lattice plate, and has the characteristics of uniform and precise combination, light and exquisite structure, natural harmony and elegant style. Both supplies and works of art. Has been widely used. Type of inserted steel grating According to different insertion methods and insertion angles, it can be divided into pressed steel lattice plate, heavy load steel lattice plate, integral steel lattice plate, sunshade steel lattice plate, etc. 1. Pressed type insert steel lattice plate: after the bearing flat steel is cut into slots, the horizontal bar flat steel is pressed into shape. Generally speaking, the maximum processing height of the production of ordinary steel plate is 100mm. The length of the steel plate is usually less than 2000mm. 2. Heavy-duty type inserted steel plate is a kind of steel plate product which is formed by the mutual bite of high flat steel and horizontal bar flat steel and pressed under the pressure of 1200 tons. It is suitable for high span load. 3. Integral type steel plate The bearing flat steel and the horizontal bar flat steel of the integral type steel plate have the same height and the cutting depth is 1/2 of the bearing flat steel. The height of the steel plate shall not be greater than 100mm. The length of the steel plate is usually less than 2000mm. 4. Shading type steel grid plate: the bearing flat steel plate of shading type steel grid plate is chute 30° or 45°, and the groove bar is slotted and press-locked. According to different needs, we can deliver other spacing, specifications of the grid plate, can use ordinary carbon steel, stainless steel, aluminum and other materials. The height of the grating plate is less than 100mm. Usage of inserted steel grating: Widely used in the civil and commercial buildings, theatres, subway, city municipal engineering field, such as products with a lightweight, high strength, corrosion protection, maintenance free, beautiful, and many other features, is now widely used in civil and commercial buildings, theatres, subway, city and municipal engineering field, can be used in the ceiling, indoor and outdoor decoration decoration, platform aisle, transom (Wells), advertising plaque, all kinds of cover plate, etc.Plain type steel grating with bearing bar pitch at 30mm

Introduction to steel grating: Off inserted steel grating is a kind of carrying capacity of large steel plate products, it consists of a certain size of Q235 low carbon steel flat by the slot (hole), plug, welding, finishing processes such as manufacturing and become a kind of steel plate products, also can choose stainless steel, brass plate, aluminum plate for the material, this product can be widely used in the ditch cover plate, stair step plate, pool cover plate. The specification of the steel grating Bearing flat steel spacing: 30 40 60 (mm) horizontal bar flat steel spacing: 30 40 60 (mm) flat steel width: 20-60 (mm) flat steel thickness: 3mm 4mm 5mm various specifications can be customized according to customer needsThe characteristics and application of steel grating: Our company produces the PLUG grid plate solder joint firm, the hole distance is even, the net surface is flat, the design is beautiful, practical, not only make supplies, but also works of art, over the years has developed hundreds of varieties, export products favored by customers. It is widely used in civil and commercial buildings, theaters, subway, city rail and other municipal engineering fields, which can be used for suspended ceiling, indoor and outdoor decoration, platform walkway, ventilation window (well), advertising plaque, various cover plates, etc.Introduction to the inserted steel grating The inserted steel plate, also known as the inserted steel plate, is made of a certain size of ordinary low-carbon flat steel, stainless steel, brass plate, aluminum plate through the process of slotting (hole), inserting, welding, finishing and so on. Product solder joint firm, uniform hole distance, beautiful design, convenient and practical. The inserted steel lattice plate has the characteristics of high strength, corrosion prevention and maintenance free of ordinary steel lattice plate, and has the characteristics of uniform and precise combination, light and exquisite structure, natural harmony and elegant style. Both supplies and works of art. Has been widely used. Type of inserted steel grating According to different insertion methods and insertion angles, it can be divided into pressed steel lattice plate, heavy load steel lattice plate, integral steel lattice plate, sunshade steel lattice plate, etc. 1. Pressed type insert steel lattice plate: after the bearing flat steel is cut into slots, the horizontal bar flat steel is pressed into shape. Generally speaking, the maximum processing height of the production of ordinary steel plate is 100mm. The length of the steel plate is usually less than 2000mm. 2. Heavy-duty type inserted steel plate is a kind of steel plate product which is formed by the mutual bite of high flat steel and horizontal bar flat steel and pressed under the pressure of 1200 tons. It is suitable for high span load. 3. Integral type steel plate The bearing flat steel and the horizontal bar flat steel of the integral type steel plate have the same height and the cutting depth is 1/2 of the bearing flat steel. The height of the steel plate shall not be greater than 100mm. The length of the steel plate is usually less than 2000mm. 4. Shading type steel grid plate: the bearing flat steel plate of shading type steel grid plate is chute 30° or 45°, and the groove bar is slotted and press-locked. According to different needs, we can deliver other spacing, specifications of the grid plate, can use ordinary carbon steel, stainless steel, aluminum and other materials. The height of the grating plate is less than 100mm. Usage of inserted steel grating: Widely used in the civil and commercial buildings, theatres, subway, city municipal engineering field, such as products with a lightweight, high strength, corrosion protection, maintenance free, beautiful, and many other features, is now widely used in civil and commercial buildings, theatres, subway, city and municipal engineering field, can be used in the ceiling, indoor and outdoor decoration decoration, platform aisle, transom (Wells), advertising plaque, all kinds of cover plate, etc.Plain type steel grating with bearing bar pitch at 30mm | Type | Widthof bearingbar | Thickness ofbearing bar | Theory Weight | Loadand deflection | Clearn Span | ||||||||||||||

| 200 | 400 | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 | 2400 | 2600 | 2800 | 3000 | |||||

| G655/30/50 | 65 | 5 | 103.4 | U | 3990 | 997 | 443 | 249 | 159 | 110 | 81 | 62 | 49 | 39 | 32 | 27 | 23 | 20 | 17 |

| G655/30/100 | 100.4 | D | 0.11 | 0.42 | 0.95 | 1.7 | 2.65 | 3.81 | 5.22 | 6.84 | 8.7 | 10.61 | 12.82 | 15.4 | 18.18 | 21.4 | 24.18 | ||

| G605/30/50 | 60 | 5 | 95.9 | U | 3400 | 850 | 377 | 212 | 136 | 94 | 69 | 53 | 41 | 34 | 28 | 23 | 20 | 17 | |

| G605/30/100 | 92.9 | D | 0.11 | 0.46 | 1.03 | 1.84 | 2.89 | 4.15 | 5.66 | 7.45 | 9.28 | 11.78 | 14.28 | 16.73 | 20.16 | 23.23 | |||

| G555/30/50 | 55 | 5 | 88.4 | U | 2856 | 714 | 317 | 178 | 114 | 79 | 58 | 44 | 35 | 28 | 23 | 19 | 16 | ||

| G555/30/100 | 85.4 | D | 0.13 | 0.5 | 1.13 | 2 | 3.14 | 4.53 | 6.19 | 8.04 | 10.3 | 12.63 | 15.29 | 18.03 | 21.08 | ||||

| G505/30/50 | 50 | 5 | 80.9 | U | 2361 | 590 | 262 | 147 | 94 | 65 | 48 | 36 | 29 | 23 | 19 | 16 | |||

| G505/30/100 | 77.9 | D | 0.14 | 0.55 | 1.24 | 2.2 | 3.45 | 4.97 | 6.82 | 8.78 | 11.39 | 13.86 | 16.88 | 20.28 | |||||

| G503/30/50 | 50 | 5 | 52.6 | U | 1416 | 354 | 157 | 88 | 56 | 39 | 28 | 22 | 17 | 14 | 11 | ||||

| G503/30/100 | 49.6 | D | 0.14 | 0.55 | 1.24 | 2.2 | 3.43 | 4.97 | 6.65 | 8.95 | 11.16 | 14.09 | 16.37 | ||||||

| G455/30/50 | 45 | 5 | 73.4 | U | 1912 | 478 | 212 | 119 | 76 | 53 | 39 | 29 | 23 | 19 | 15 | ||||

| G455/30/100 | 70.4 | D | 0.15 | 0.61 | 1.38 | 2.45 | 3.83 | 5.56 | 7.62 | 9.73 | 12.44 | 15.76 | 18.39 | ||||||

| G405/30/50 | 40 | 5 | 65.9 | U | 1511 | 377 | 167 | 94 | 60 | 41 | 30 | 23 | 18 | 15 | |||||

| G405/30/100 | 62.9 | D | 0.17 | 0.69 | 1.54 | 2.76 | 4.31 | 6.14 | 8.37 | 11.02 | 13.92 | 17.8 | |||||||

| G403/30/50 | 40 | 3 | 43.3 | U | 906 | 226 | 100 | 56 | 36 | 25 | 18 | 14 | 11 | ||||||

| G403/30/100 | 40.3 | D | 0.17 | 0.69 | 1.54 | 2.74 | 4.32 | 6.25 | 8.39 | 11.2 | 14.21 | ||||||||

| G355/30/50 | 35 | 5 | 58.4 | U | 1156 | 289 | 128 | 72 | 46 | 32 | 23 | 18 | 14 | ||||||

| G355/30/100 | 55.4 | D | 0.2 | 0.79 | 1.77 | 3.16 | 4.94 | 7.17 | 9.61 | 12.92 | 16.24 | ||||||||

| G353/30/50 | 35 | 3 | 38.6 | U | 694 | 173 | 77 | 43 | 27 | 19 | 14 | 10 | |||||||

| G353/30/100 | 35.6 | D | 0.2 | 0.79 | 1.77 | 3.14 | 4.84 | 7.11 | 9.77 | 12.03 | |||||||||

| G325/30/50 | 32 | 5 | 53.9 | U | 967 | 241 | 107 | 60 | 38 | 26 | 19 | 15 | 11 | ||||||

| G325/30/100 | 50.9 | D | 0.22 | 0.86 | 1.94 | 3.44 | 5.35 | 7.64 | 10.42 | 14.13 | 16.81 | ||||||||

| G323/30/50 | 32 | 3 | 35.8 | U | 580 | 145 | 64 | 36 | 23 | 16 | 11 | 9 | |||||||

| G323/30/100 | 32.8 | D | 0.21 | 0.86 | 1.93 | 3.45 | 5.41 | 7.85 | 10.09 | 14.19 | |||||||||

| G255/30/50 | 25 | 5 | 43.4 | U | 590 | 147 | 65 | 36 | 23 | 16 | 12 | ||||||||

| G255/30/100 | 40.4 | D | 0.28 | 1.1 | 2.47 | 4.35 | 6.82 | 9.92 | 13.9 | ||||||||||

| G253/30/50 | 25 | 3 | 29.3 | U | 354 | 88 | 39 | 22 | 14 | 9 | |||||||||

| G253/30/100 | 26.3 | D | 0.28 | 1.1 | 2.47 | 4.43 | 6.94 | 9.35 | |||||||||||

| G205/30/50 | 20 | 5 | 36.0 | U | 377 | 94 | 41 | 23 | 15 | 10 | |||||||||

| G205/30/100 | 33.0 | D | 0.34 | 1.37 | 3.05 | 5.44 | 8.73 | 12.21 | |||||||||||

| G203/30/50 | 20 | 3 | 24.6 | U | 226 | 56 | 25 | 14 | 9 | ||||||||||

| G203/30/100 | 21.6 | D | 0.34 | 1.37 | 3.1 | 5.53 | 8.76 | ||||||||||||

| Type | Widthof bearing bar | Thickness of bearing bar | Theory Weight | Loadand deflection | Clear Span | ||||||||||||||

| 200 | 400 | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 | 2400 | 2600 | 2800 | 3000 | |||||

| G655/40/50 | 65 | 5 | 81.7 | U | 2992 | 748 | 332 | 187 | 119 | 83 | 61 | 46 | 36 | 29 | 24 | 20 | 17 | 15 | |

| G655/40/100 | 78.7 | D | 0.11 | 0.42 | 0.95 | 1.7 | 2.65 | 3.84 | 3.93 | 6.78 | 8.54 | 10.54 | 12.84 | 15.25 | 17.97 | 21.46 | |||

| G605/40/50 | 60 | 5 | 75.9 | U | 2550 | 637 | 283 | 159 | 102 | 70 | 52 | 39 | 31 | 25 | 21 | 17 | 15 | ||

| G605/40/100 | 72.9 | D | 0.11 | 0.46 | 1.03 | 1.84 | 2.89 | 4.12 | 4.27 | 7.32 | 9.36 | 11.57 | 14.31 | 16.54 | 20.21 | ||||

| G555/40/50 | 55 | 5 | 70.1 | U | 2142 | 535 | 238 | 133 | 85 | 59 | 43 | 33 | 26 | 21 | 17 | 14 | |||

| G555/40/100 | 67.1 | D | 0.13 | 0.5 | 1.13 | 2 | 3.13 | 4.51 | 4.59 | 8.05 | 10.22 | 12.66 | 15.11 | 17.77 | |||||

| G505/40/50 | 50 | 5 | 64.2 | U | 1770 | 442 | 196 | 110 | 70 | 49 | 36 | 27 | 21 | 17 | 14 | ||||

| G505/40/100 | 61.2 | D | 0.14 | 0.55 | 1.24 | 2.2 | 3.43 | 5 | 5.12 | 8.79 | 11.02 | 13.69 | 16.64 | ||||||

| G503/40/50 | 50 | 3 | 42.6 | U | 1062 | 265 | 118 | 66 | 42 | 29 | 21 | 16 | 13 | 10 | |||||

| G503/40/100 | 39.6 | D | 0.14 | 0.55 | 1.24 | 2.2 | 3.43 | 4.94 | 4.99 | 8.71 | 11.4 | 13.49 | |||||||

| G455/40/50 | 45 | 5 | 58.4 | U | 1434 | 358 | 159 | 89 | 57 | 39 | 29 | 22 | 17 | 14 | |||||

| G455/40/100 | 55.4 | D | 0.15 | 0.61 | 1.38 | 2.44 | 3.83 | 5.46 | 5.67 | 9.85 | 12.28 | 15.53 | |||||||

| G405/40/50 | 40 | 5 | 52.6 | U | 1133 | 283 | 125 | 70 | 45 | 31 | 23 | 17 | 13 | 11 | |||||

| G405/40/100 | 49.6 | D | 0.17 | 0.69 | 1.54 | 2.74 | 4.32 | 6.2 | 6.42 | 10.88 | 13.45 | 17.47 | |||||||

| G403/40/50 | 40 | 3 | 35.3 | U | 680 | 170 | 75 | 42 | 27 | 18 | 13 | 10 | |||||||

| G403/40/100 | 32.3 | D | 0.17 | 0.69 | 1.54 | 2.74 | 4.32 | 6.01 | 6.08 | 10.71 | |||||||||

| G355/40/50 | 35 | 5 | 46.8 | U | 867 | 216 | 96 | 54 | 34 | 24 | 17 | 13 | |||||||

| G355/40/100 | 43.8 | D | 0.2 | 0.78 | 1.77 | 3.16 | 4.88 | 7.18 | 7.12 | 12.48 | |||||||||

| G353/40/50 | 35 | 3 | 31.6 | U | 520 | 130 | 57 | 32 | 20 | 14 | 10 | 8 | |||||||

| G353/40/100 | 28.6 | D | 0.2 | 0.79 | 1.75 | 3.12 | 4.79 | 7 | 7.01 | 12.85 | |||||||||

| G325/40/50 | 32 | 5 | 43.3 | U | 725 | 181 | 80 | 45 | 29 | 20 | 14 | 11 | |||||||

| G325/40/100 | 40.3 | D | 0.21 | 0.86 | 1.93 | 3.45 | 5.45 | 7.84 | 7.7 | 13.86 | |||||||||

| G323/40/50 | 32 | 3 | 29.4 | U | 435 | 108 | 48 | 27 | 17 | 12 | 8 | ||||||||

| G323/40/100 | 26.4 | D | 0.21 | 0.86 | 1.93 | 3.45 | 5.34 | 7.86 | 7.37 | ||||||||||

| G255/40/50 | 25 | 5 | 35.1 | U | 442 | 110 | 49 | 27 | 17 | 12 | 9 | ||||||||

| G255/40/100 | 32.1 | D | 0.27 | 1.1 | 2.48 | 4.35 | 6.74 | 9.94 | 10.46 | ||||||||||

| G253/40/50 | 25 | 3 | 24.3 | U | 265 | 66 | 29 | 16 | 10 | 7 | |||||||||

| G253/40/100 | 21.3 | D | 0.27 | 1.1 | 2.45 | 4.3 | 6.63 | 9.71 | |||||||||||

| G205/40/50 | 20 | 5 | 29.3 | U | 283 | 70 | 31 | 17 | 11 | 7 | |||||||||

| G205/40/100 | 26.3 | D | 0.34 | 1.36 | 3.08 | 5.37 | 8.56 | 11.46 | |||||||||||

| G203/40/50 | 20 | 3 | 20.6 | U | 170 | 42 | 18 | 10 | 6 | ||||||||||

| G203/40/100 | 17.6 | D | 0.34 | 1.37 | 2.98 | 5.28 | 7.84 | ||||||||||||

| Type | bearing bar section | Cross bar pitch | Theory weight | Serrationfactor | Loadand deflection | ClearSpan | ||||||||||||||||

| Load | Deflection | 150 | 300 | 450 | 600 | 750 | 900 | 1050 | 1200 | 1500 | 1800 | 2100 | 2400 | 2700 | 3000 | 3300 | 3600 | |||||

| G655/60/50 | 65×5 | 50 | 49.0 | 0.92 | 1.04 | U | 3436.41 | 858.79 | 381.42 | 214.34 | 137.01 | 95.00 | 69.67 | 53.23 | 33.89 | 23.39 | 17.06 | 12.95 | 10.13 | 8.12 | 6.62 | 5.49 |

| D | 0.06 | 0.24 | 0.55 | 0.99 | 1.54 | 2.22 | 3.03 | 3.96 | 6.18 | 8.91 | 12.12 | 15.84 | 20.02 | 24.75 | 29.94 | 35.64 | ||||||

| G555/60/50 | 55×5 | 50 | 42.4 | 0.90 | 1.05 | U | 2460.46 | 614.8 | 273.02 | 153.99 | 98.02 | 67.94 | 49.81 | 38.04 | 24.20 | 16.68 | 12.14 | 9.20 | 7.18 | 5.47 | 4.67 | 3.86 |

| D | 0.07 | 0.29 | 0.65 | 1.17 | 1.82 | 2.63 | 3.58 | 4.68 | 7.31 | 10.53 | 14.33 | 18.72 | 23.69 | 29.25 | 35.39 | 42.12 | ||||||

| G505/60/50 | 50×5 | 50 | 39.0 | 0.89 | 1.06 | U | 2033.40 | 508.06 | 225.60 | 126.73 | 80.97 | 56.11 | 41.13 | 31.40 | 19.96 | 13.74 | 10.00 | 7.56 | 5.90 | 4.70 | 3.82 | |

| D | 0.08 | 0.32 | 0.72 | 1.28 | 2.01 | 2.89 | 3.94 | 5.14 | 8.04 | 11.58 | 15.76 | 28.59 | 26.06 | 32.17 | 38.93 | |||||||

| G455/60/50 | 45x5 | 50 | 35.7 | 0.88 | 1.07 | U | 1647.01 | 411.49 | 182.69 | 102.61 | 65.54 | 45.41 | 33.27 | 25.39 | 16.12 | 11.09 | 8.06 | 6.09 | 4.73 | 3.77 | 3.05 | |

| D | 0.08 | 0.35 | 0.80 | 1.43 | 2.23 | 3.21 | 4.37 | 5.72 | 8.93 | 12.87 | 17.51 | 22.88 | 28.95 | 35.75 | 43.25 | |||||||

| G405/60/50 | 40×5 | 50 | 32.3 | 0.87 | 1.07 | U | 1301.30 | 325.0 | 9144.31 | 81.03 | 51.75 | 35.84 | 26.25 | 20.02 | 12.70 | 8.72 | 6.32 | 4.77 | 3.70 | 2.94 | ||

| D | 0.10 | 0.40 | 0.90 | 1.60 | 2.51 | 3.62 | 4.92 | 6.43 | 10.05 | 14.47 | 19.70 | 25.74 | 32.57 | 40.12 | ||||||||

| G403/60/50 | 40×3 | 50 | 21.7 | 0.87 | 1.07 | U | 780.76 | 195.3 | 86.56 | 48.60 | 31.02 | 21.48 | 15.72 | 11.99 | 7.60 | 5.21 | 3.77 | 2.84 | 2.20 | 1.74 | ||

| D | 0.10 | 0.40 | 0.90 | 1.60 | 2.51 | 3.62 | 4.92 | 6.43 | 10.05 | 14.47 | 19.70 | 25.74 | 32.57 | 40.21 | ||||||||

| G325/60/50 | 32×5 | 50 | 27.0 | 0.83 | 1.09 | U | 832.77 | 207.99 | 92.29 | 51.80 | 33.06 | 22.87 | 16.74 | 12.75 | 8.06 | 5.52 | 3.98 | 2.99 | 2.31 | |||

| D | 0.12 | 0.50 | 1.13 | 2.01 | 3.14 | 4.52 | 6.15 | 8.04 | 12.56 | 18.09 | 24.63 | 32.1 | 740.72 | |||||||||

| G323/60/50 | 32×5 | 50 | 18.5 | 0.83 | 1.09 | U | 499.64 | 124.77 | 55.35 | 31.06 | 19.81 | 13.70 | 10.02 | 7.63 | 4.81 | 3.29 | 2.37 | 1.77 | 1.36 | |||

| D | 0.12 | 0.50 | 1.13 | 2.01 | 3.14 | 4.52 | 6.15 | 8.04 | 12.56 | 18.09 | 24.63 | 32.17 | 40.72 | |||||||||

| G255/60/50 | 25×5 | 50 | 22.3 | 0.79 | 1.12 | U | 508.22 | 126.89 | 56.27 | 31.56 | 20.12 | 13.90 | 10.16 | 7.72 | 4.86 | 3.31 | 2.37 | 1.77 | ||||

| D | 0.16 | 0.54 | 1.44 | 2.57 | 4.02 | 5.79 | 7.88 | 10.29 | 16.08 | 23.16 | 31.55 | 41.18 | ||||||||||

| G253/60/50 | 25×3 | 50 | 15.7 | 0.79 | 1.12 | U | 304.91 | 76.15 | 33.74 | 18.91 | 12.05 | 8.32 | 6.07 | 4.61 | 2.89 | 1.96 | 1.40 | 1.04 | ||||

| D | 0.16 | 0.64 | 1.44 | 2.57 | 4.02 | 5.79 | 7.88 | 10.29 | 16.08 | 23.16 | 31.53 | 41.18 | ||||||||||

| G205/60/50 | 20×5 | 50 | 19.0 | U | 325.22 | 81.16 | 35.97 | 20.15 | 12.83 | 8.85 | 6.45 | 4.90 | 3.07 | 2.07 | 1.47 | |||||||

| D | 0.20 | 0.80 | 1.81 | 3.21 | 5.02 | 7.23 | 9.85 | 12.87 | 20.10 | 28.95 | 39.41 | |||||||||||